Best quality Graphite Hollow Tube - Customized Graphite Carbon Products with High Temperature Resistance – Rubang

Best quality Graphite Hollow Tube - Customized Graphite Carbon Products with High Temperature Resistance – Rubang Detail:

Product Detail:

Products Quick Details

Product Name: Customized Carbon Graphite Parts

Place of Origin: Hebei, China

Brand Name: Rubang Carbon

Model Number: RB-GCP-C

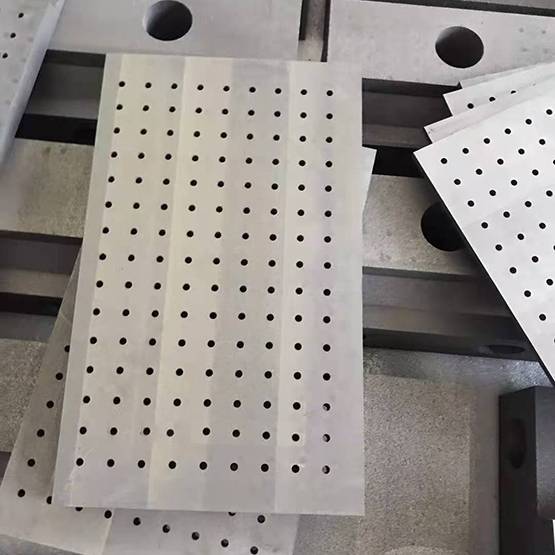

Shape: Circle, Plate, or as per Customized Drawings

Raw Material: Graphite Carbon

Spec.: Customized Drawings

Color: Black

Chemical Composition:

Fixed Carbon: 98.50%Min S: 0.05%Max.

Volatile Matter 0.5%Max. Ash 300ppm.

Physical Characteristics:

Apparent Density (g/cm³ ): 1.75 – 1.90 g/cm3

Thermal Expansion: 4.0 ~ 6.0 X10-6 / (100-600℃)

Flexural Strength (Mpa): 45-85 Mpa

Young’s Modulus(Gpa):8-12

Compressive Strength(MPa): .85~115

Shore Hardness: 55-80

|

Graphite Plate/ Parts/ Crucible/ Tube/Rod -Physical & Chemical Index |

|||||

|

Description |

Unit |

Specifications |

|||

|

Plate/Customized Parts |

Crucible |

Tube |

|||

|

Electrical Resistance |

μΩ.m |

9-15 |

9-15 |

9-15 |

8-14 |

|

Thermal Conductivity |

W/m.℃ |

- |

- |

110 |

95 |

|

Granularity |

μm/mm |

0.8mm |

22μm |

12μm |

30μm |

|

Flexural Strength |

Mpa |

22 |

40 |

10-35 |

40-65 |

|

Compressive Strength |

Mpa |

40 |

80 |

20-95 |

60-85 |

|

Elasticity Modulus |

Gpa |

10 |

10 |

12 |

12 |

|

Shore Hardness |

HSD |

55 |

55 |

55-65 |

55 |

|

Bulk Density |

g/cm3 |

1.75 |

1.80-1.85 |

1.65-1.85 |

1.78 |

|

CTE |

X 10-6/℃ |

4.1 |

4.1 |

2.5-4.5 |

5.2 |

|

Ash |

% |

0.3 |

0.3 |

0.3 |

0.2 |

| Note: The Ash and Thermal Expansion coefficient are parameter indexes. | |||||

Products Features:

1)Anti-oxidation treatment to maximize service life.

2)Produced with special process. High bulk density and low porosity resist erosion of molten aluminum and its gas particles.

3)High purity, low ash content graphite material prevents volatile substances, avoids spots, holes on aluminum coated film.

4)Graphite crucible treated by special coating process, resists oxidation and maximizes service lifespan

5)Exact machining of graphite crucibles. Polished mirror surface and exact sizes.

Applications:

1)Graphite crucibles Used for various non-ferrous metal smelting, such as aluminum, gold, silver, copper, precious metal etc. Glass smelting.

2)Graphite Tube made from good performance graphite blocks, are widely used in metallurgy, machinery, electronics and chemical industry, etc.

Business Conditions and Terms:

Prices and Delivery Terms: FOB, CFR, CIF, EXW, DCA, DDP

Payment Currency: USD, EUR, JPY, CAD, CNY, AUS

Payment Terms: T/T, L/C, D/P D/A, Western Union, Cash

Loading Port: XINGANG or QINGDAO, CHINA

Packing Details:

Packed in wooden boxes/lathing and tied with metal control strip.

Product detail pictures:

Related Product Guide:

Our organization promises all customers with the first-class products and solutions and the most satisfying post-sale service. We warmly welcome our regular and new clients to join us for Best quality Graphite Hollow Tube - Customized Graphite Carbon Products with High Temperature Resistance – Rubang , The product will supply to all over the world, such as: Czech Republic, Panama, Milan, We've a skilled sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with personalized service and unique merchandise.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.