Manufacturer for UHP 450mm Graphite Electrode with Low Resistivity for Lf Furnace - UHP Graphite Electrode for EAF.& LF. Dia.550-700mm(Inch 22″- 28″) – Rubang

Manufacturer for UHP 450mm Graphite Electrode with Low Resistivity for Lf Furnace - UHP Graphite Electrode for EAF.& LF. Dia.550-700mm(Inch 22″- 28″) – Rubang Detail:

Products Quick Details

Product Name: UHP Grade Graphite Electrode

Place of Origin: Hebei, China

Brand Name: Rubang Carbon

Model Number: RB-UHP-3

Type: Graphite Electrode

Nipple: 3TPI/4TPI/4TPIL

Raw Material: Needle Petroleum Coke

Application: EAF or LF of Steel Making or Smelting Steel

Length: 1800~2700mm

Superiority: Low Consumption Rate

Color: Black

Grade: RP (Regular Power)

Chemical Composition:

Fixed Carbon 99%Min Volatile Matter 0.2%Max. Ash 0.2%Max.

Physical Characteristics:

Resistance (μΩ.m): 4 – 6.3

Apparent Density (g/cm³ ): 1.66 – 1.75 g/cm3

Thermal Expansion: 1.1 ~ 1.5 X10-6 / (100-600℃)

Flexural Strength (Mpa): 8-12 Mpa

Elastic Modulus(GPa): .8.50~15.50

Current Carrying Capacity: 35-80KA

|

UHP Graphite Electrodes-Physical & Chemical Index |

|||||

|

Description |

Type |

Unit |

Nominal Diameter (mm) |

||

|

Ø300 – 400 |

Ø450 – 500 |

Ø550 – 600 |

|||

|

Electrical Resistance(≤) |

Electrode |

μΩ.m |

6.2 |

6.3 |

6.3 |

|

Nipple |

5.0 |

5.0 |

5.0 |

||

|

Tensile Strength (≥) |

Electrode |

Mpa |

10.5 |

10.5 |

11.0 |

|

Nipple |

18.0 |

18.0 |

20.0 |

||

|

Young’s Module (≤) |

Electrode |

Gpa |

14.0 |

14.0 |

14.0 |

|

Nipple |

18.0 |

18.0 |

18.0 |

||

|

Bulk Density (≥) |

Electrode |

g/cm3 |

1.66 |

1.66 |

1.66 |

|

Nipple |

1.75 |

1.75 |

1.75 |

||

|

CTE (≤) |

Electrode |

X 10-6/℃ |

1.5 |

1.5 |

1.5 |

|

Nipple |

1.4 |

1.4 |

1.4 |

||

|

Ash (≤) |

- |

% |

0.3 |

0.3 |

0.3 |

| Note: The Ash and Thermal Expansion coefficient are parameter indexes. | |||||

Products Processing:

Graphite Electrode is made of high-quality low ash materials, such as petroleum coke, needle coke and coal pitch.

After Raw Material calcining, crushing, screening, burden, kneading, forming, baking, impregnation, graphitization and then precision machined with professional CNC machining.

such of the products own characteristics with low resistivity, good electrical conductivity ,low ash, compact structure, good anti oxidation and high mechanical strength, so it is the best conductive material for electric arc furnace and smelting furnace.

Applications:

1. For Ladle furnaces

2. For Electric arc furnace steel making

3. For Yellow phosphorus furnace

4. Apply to Industrial silicon furnace or melting copper.

5. Apply to Refine steel in ladle furnaces and in other smelting processes

Business Conditions and Terms:

Prices and Delivery Terms: FOB, CFR, CIF, EXW, DDP

Payment Currency: USD, EUR, JPY, CAD, CNY, AUS

Payment Terms: T/T, L/C, D/P D/A, Western Union, Cash

Loading Port: XINGANG OR QINGDAO, CHINA

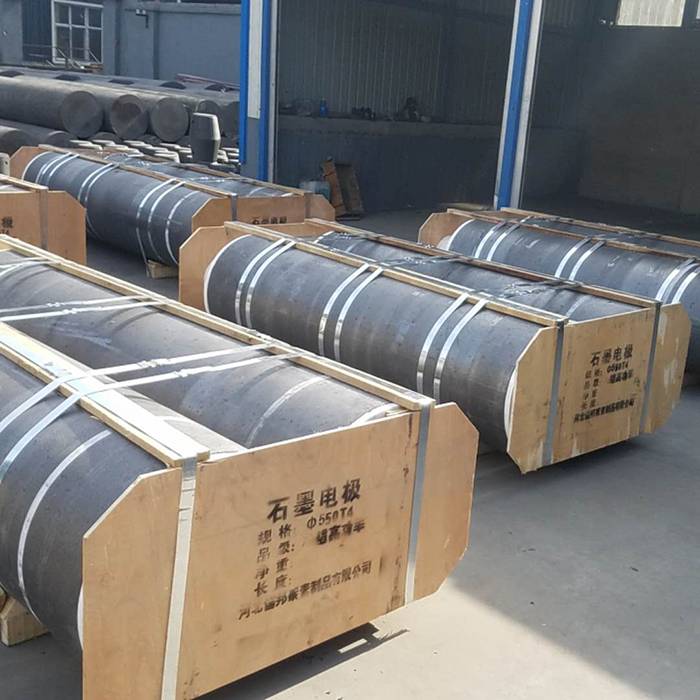

Package Details:

Packed in wooden boxes/lathing and tied with metal control strip.

Products Transportation and Installation Introductions:

(1)The Electrodes should be kept in a clean, drying place and avoid vibrations and collisions. It should be dried before use.

(2) When installing the joint, please clean the hole with the compressed air, then carefully screw the joint and not damage the thread.

(3)When connecting electrodes, the two electrodes should be cleaned with compressed air when they are 20-30mm apart.

(4)When using a wrench to connect the electrode, it should be completely taut to the specified position so that the gap between the two electrodes is not less than 0.05mm

(5)To avoid the electrode fracture, please avoid the insulation block.

(6)To avoid the electrode fracture, please place the bulk block in the upper part.

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product or service High quality, Reasonable Rate and Efficient Service" for Manufacturer for UHP 450mm Graphite Electrode with Low Resistivity for Lf Furnace - UHP Graphite Electrode for EAF.& LF. Dia.550-700mm(Inch 22″- 28″) – Rubang , The product will supply to all over the world, such as: Croatia, Costa Rica, Mauritius, We are proud to supply our products to every costumer all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.